Walking into the world of foil plotter films, you’ll quickly discover that not all that glitters is the same. Beyond the spectrum of colors and finishes lies a critical, yet often overlooked, technical specification: film thickness. Choosing the correct caliper—the precise measurement of a material's thickness—is not just a minor detail; it's a fundamental decision that influences everything from your plotter's performance to the final durability of your application. Understanding this variable is the key to unlocking a seamless, professional result every time.

Why Thickness Matters More Than You Think

At first glance, a thicker film might simply seem more durable, but the reality is far more nuanced. The thickness of a foil film directly affects how it interacts with your plotterfolien, how easily it weeds, and how well it conforms to curved or textured surfaces. A film that is too thick for a delicate design might be impossible to weed cleanly, while a film that is too thin for an outdoor application might not hold up over time. Selecting the right thickness is about finding the perfect balance between machinability, application suitability, and longevity for your specific project.

Standard vs. Heavy-Duty: Knowing the Difference

Most foil films fall into two general categories: standard and heavy-duty. Standard-weight films are the workhorses of the industry. They are thin, highly flexible, and designed for ease of cutting and weeding. They conform beautifully to slightly curved surfaces and are ideal for the majority of indoor applications, such as paper crafts, labels, and decals on smooth substrates. Heavy-duty films, as the name implies, are thicker and more robust. They feature a stronger construction that offers enhanced resistance to abrasion, chemicals, and prolonged UV exposure, making them the go-to for demanding exterior signage and industrial labeling.

Matching Thickness to Your Cutting Plotter’s Capability

Your machine has a say in this decision. Before committing to a heavy-duty film, it’s crucial to consult your plotter’s specifications. Entry-level or older machines may struggle with the higher blade pressure and multiple passes required to cleanly cut through a thick, heavy-duty film. This can lead to incomplete cuts, excessive blade wear, and motor strain. Standard-weight films are universally compatible and are the safest bet for most desktop plotters. If your projects demand a heavy-duty film, ensure your machine is a professional-grade model capable of handling the added demand.

The Impact on Intricate Designs and Fine Text

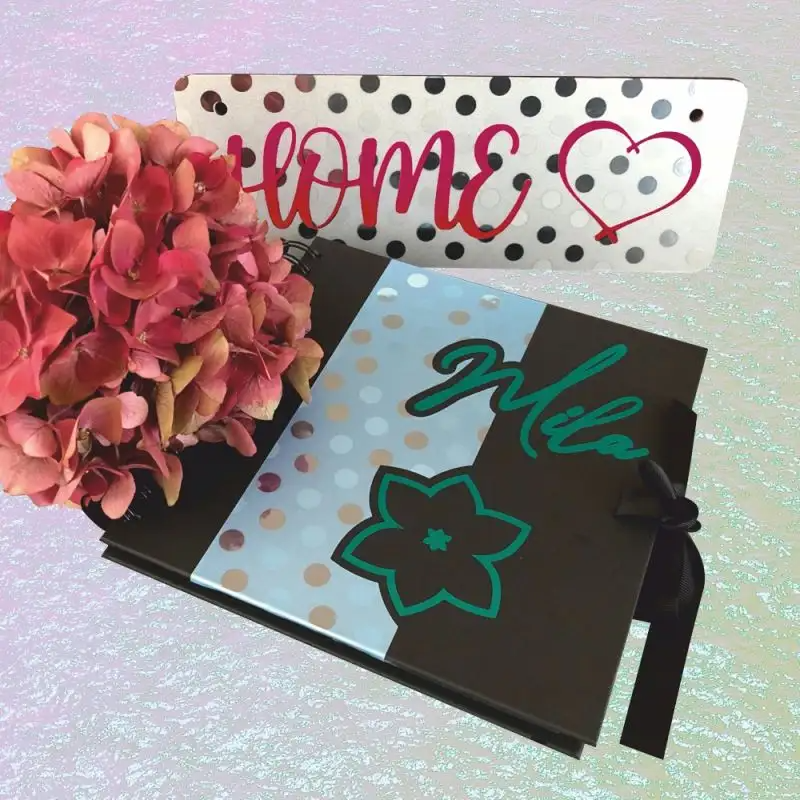

If your project features delicate script, tiny logos, or intricate patterns with fine lines, film thickness becomes your primary concern. A standard, thinner film is almost always the best choice here. Its lower mass allows for cleaner, sharper cuts on tight curves and small details. It also weeds with far greater ease, as the thin material is less likely to tear or resist lifting from the carrier sheet. Attempting to cut a highly detailed design from a thick, heavy-duty film will often result in frustration, with details tearing during weeding or failing to cut through entirely.

Conformability and Application on Complex Surfaces

Consider the shape and texture of your application surface. A standard, thinner film is inherently more flexible and pliable. It will easily wrap around gentle curves, such as the edge of a phone case or a water bottle, without buckling or creating "tenting" where the adhesive fails to make contact. Heavy-duty films, with their rigid structure, are best suited for flat or very gently curved surfaces. Their stiffness makes them difficult to apply to compound curves without specialized techniques and heat assistance, which aren't always feasible for every user.

The Relationship Between Thickness and Adhesive

It's important to note that thickness often correlates with adhesive strength. Heavy-duty films are typically paired with a more aggressive, permanent adhesive designed for challenging surfaces like powder-coated metals, plastics, and painted walls. Standard films often come with a range of adhesive options, including removable formulas. Therefore, selecting a thicker film often means you are also opting for a stronger, more tenacious bond, which is a critical factor for permanent outdoor installations or applications on low-surface-energy plastics.

Making an Informed Choice for Your Project

Ultimately, the right thickness is a product of your project's unique recipe: your design's complexity, your plotter's capability, your application surface, and the required lifespan of the final product. For most everyday crafting, signage on smooth interior walls, and product labels, a standard-weight film will deliver exceptional results. Reserve heavy-duty films for the tough jobs—vehicle graphics, machinery labels, and outdoor signs that need to endure the elements. By thoughtfully matching the film's thickness to your project's demands, you ensure a smoother production process and a final product that performs as brilliantly as it looks.