Investing in a HiTo Engineering aluminum coil coating line represents a significant commitment to quality and efficiency. Like any sophisticated industrial system, these precision-engineered lines require proper maintenance to ensure they continue operating at peak performance throughout their service life. A well-executed maintenance program not only prevents unexpected downtime and costly repairs but also maintains the consistent coating quality that these systems are designed to deliver. By implementing a structured approach to upkeep, manufacturers can protect their investment, maximize productivity, and extend the operational lifespan of their coating equipment far beyond typical expectations.

Establishing a Preventive Maintenance Schedule

The foundation of effective maintenance begins with a comprehensive preventive schedule tailored to your specific coating line configuration. HiTo Engineering provides detailed maintenance manuals that outline recommended service intervals for each component, but these should be adapted to your actual operating conditions. Create a calendar that schedules daily, weekly, monthly, and annual maintenance tasks, assigning clear responsibility for each activity. Document every service performed, noting any observations or measurements that might indicate developing issues. This systematic approach transforms maintenance from reactive firefighting into a predictable, manageable process that minimizes disruptions to production schedules.

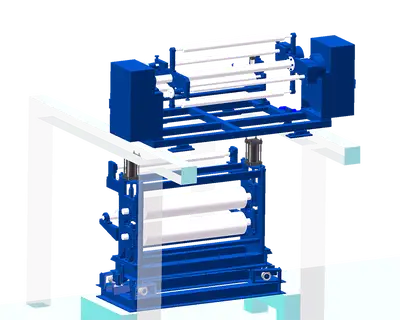

Roll Coater Maintenance and Precision Alignment

The heart of your coating quality lies in the precision roll coating system, making its maintenance particularly critical. Establish a routine for regularly inspecting coating rolls for wear, surface damage, or buildup of hardened material. Develop a strict cleaning protocol using manufacturer-recommended solvents and tools that won't damage precision roll surfaces. Regularly verify roll alignment and nip pressures using appropriate gauges, as even minor misalignments can cause coating defects. Keep detailed records of roll performance and maintenance history, as this data will help predict when rolls need resurfacing or replacement before they impact product quality.

Oven System Efficiency and Safety Checks

The curing oven represents both a significant energy investment and potential safety concern if not properly maintained. Regularly inspect and clean oven burners, nozzles, and air circulation systems to maintain thermal efficiency and temperature uniformity. Check and calibrate temperature sensors and safety interlocks to ensure accurate readings and proper shutdown protocols. Inspect oven insulation for damage or deterioration that could lead to heat loss and increased energy consumption. Establish a schedule for professional combustion analysis to optimize fuel-air mixtures for both efficiency and safety, reducing operating costs while maintaining a secure operating environment.

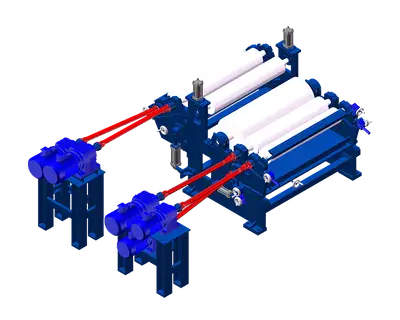

Conveyor and Tension Control System Maintenance

Proper web handling is essential for preventing coating defects and operational problems. Regularly inspect and clean all conveyor rollers, guides, and tracking sensors to ensure smooth material flow. Check pneumatic and mechanical tension control systems for proper operation, calibrating sensors and adjusting components as needed. Lubricate all appropriate bearings and moving parts according to manufacturer specifications, using only recommended lubricants. Pay particular attention to accumulator systems, ensuring proper operation of pneumatic components and safety systems that protect both equipment and operators during material accumulation and release cycles.

Chemical Management System Upkeep

The chemical pretreatment section requires diligent maintenance to prevent processing issues and equipment damage. Regularly inspect and clean spray nozzles, filters, and heat exchangers to maintain proper chemical application and temperature control. Monitor chemical concentration levels and pH values, calibrating monitoring equipment frequently to ensure accurate readings. Establish a schedule for tank cleaning and system flushing to prevent buildup of contaminants that could affect pretreatment quality. Inspect pumps, valves, and piping for signs of corrosion or wear, replacing components before failures occur that could lead to costly downtime or environmental concerns.

Control System and Electrical Component Care

The sophisticated control systems that operate your coating line require regular attention to maintain precision operation. Keep electrical cabinets clean and properly ventilated, checking connections for tightness and signs of overheating. Regularly back up system parameters and recipes to prevent loss of valuable production settings. Update software as recommended by HiTo Engineering, taking advantage of improvements in functionality and bug fixes. Test safety interlocks and emergency stop systems regularly to ensure they function properly when needed. Consider scheduling periodic professional inspections of electrical systems to identify potential issues before they lead to unplanned downtime.

Documentation and Continuous Improvement

Maintenance effectiveness increases dramatically when supported by thorough documentation and analysis. Maintain detailed records of all maintenance activities, equipment performance metrics, and any operational issues encountered. Use this data to identify patterns that might indicate developing problems or opportunities for process improvement. Regularly review and refine your maintenance procedures based on actual experience and technological advancements. Consider implementing a computerized maintenance management system (CMMS) to better track schedules, inventory spare parts, and analyze maintenance effectiveness over time, transforming your maintenance program from a cost center into a valuable source of operational intelligence.